Competition 2026Peaking Jay

A fully carbon fiber design: The ultimate competitive edge

The ultimate competitive edge

In just two years, our team has made tremendous progress. We started small with a foamboard aircraft that weighed only 4 lb, and other teams nicknamed it "the cardboard plane." Despite its simplicity, limited payload, and budget nearly 5–20 times smaller than most teams, we managed to place in the top half of the competition.

Motivated by this success, we aimed higher the following year. We designed and built a 6 ft wingspan wooden aircraft weighing 7 lbs, a major step forward in complexity and ambition. Despite the setbacks when the plane crashed on the first day due to the Arizona heat, we persevered and completed two of the three missions, ultimately finishing in the top third overall.

This year, we're aiming even higher. Our team is taking on the challenge of building a fully carbon composite aircraft — a leap that places us among top-performing teams with decades of experience, much larger memberships, and budgets several times our own. With this effort, we are setting our goal to finish in the top 20 teams, and we are working hard every day to make it happen.

2024 - The Phoenix

2025 - The Freedom Fighter

Design Specifications

So far, we have completed the detailed design of our plane. It is estimated to weigh 10.8 lbs with a top speed of 92 ft/s. It can carry 4.4 lbs of payload in its large carbon fiber fuselage. Additionally, it can tow a large banner (2 x 10 ft) for 5 minutes.

Manufacturing Process Validation

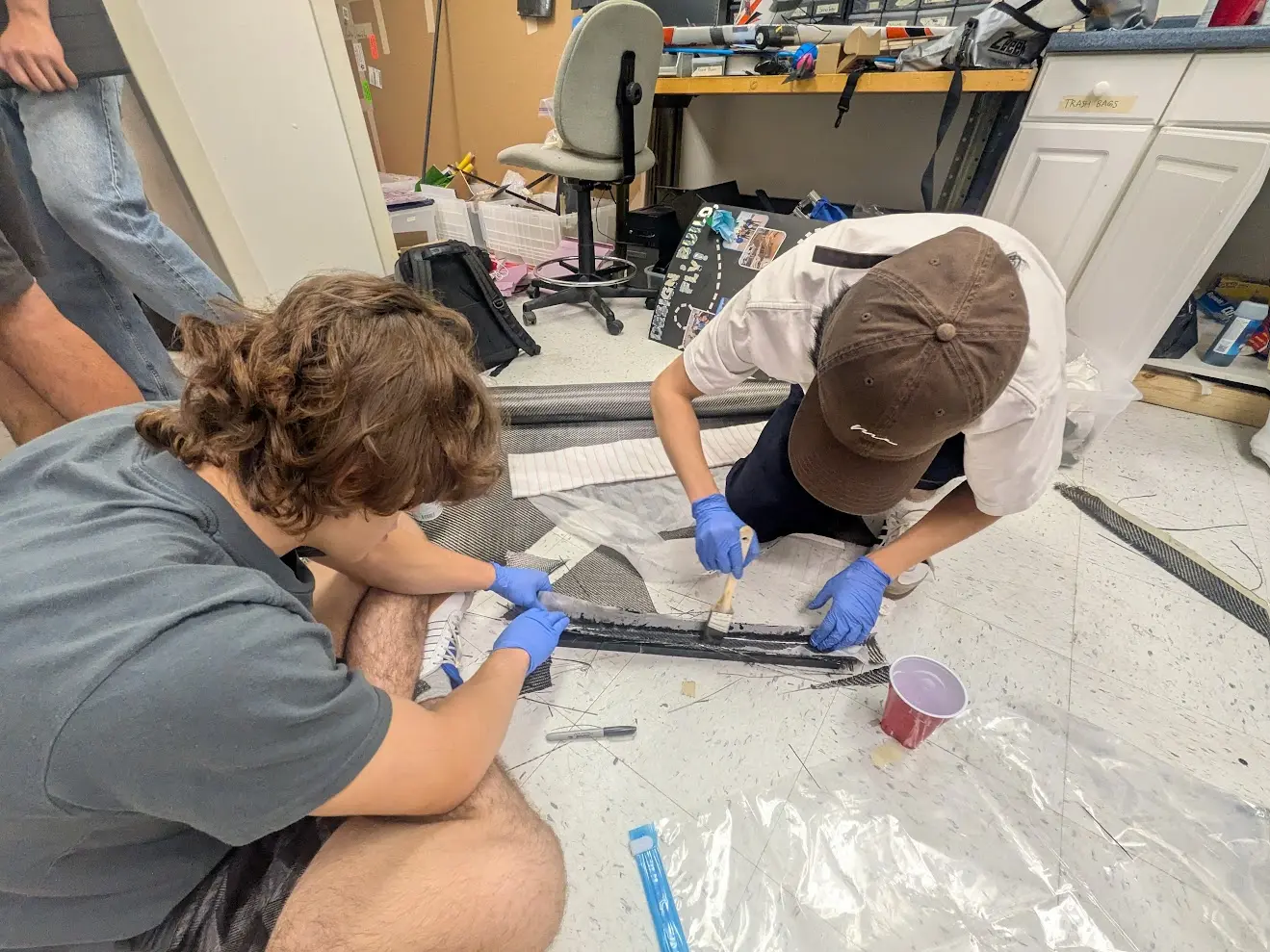

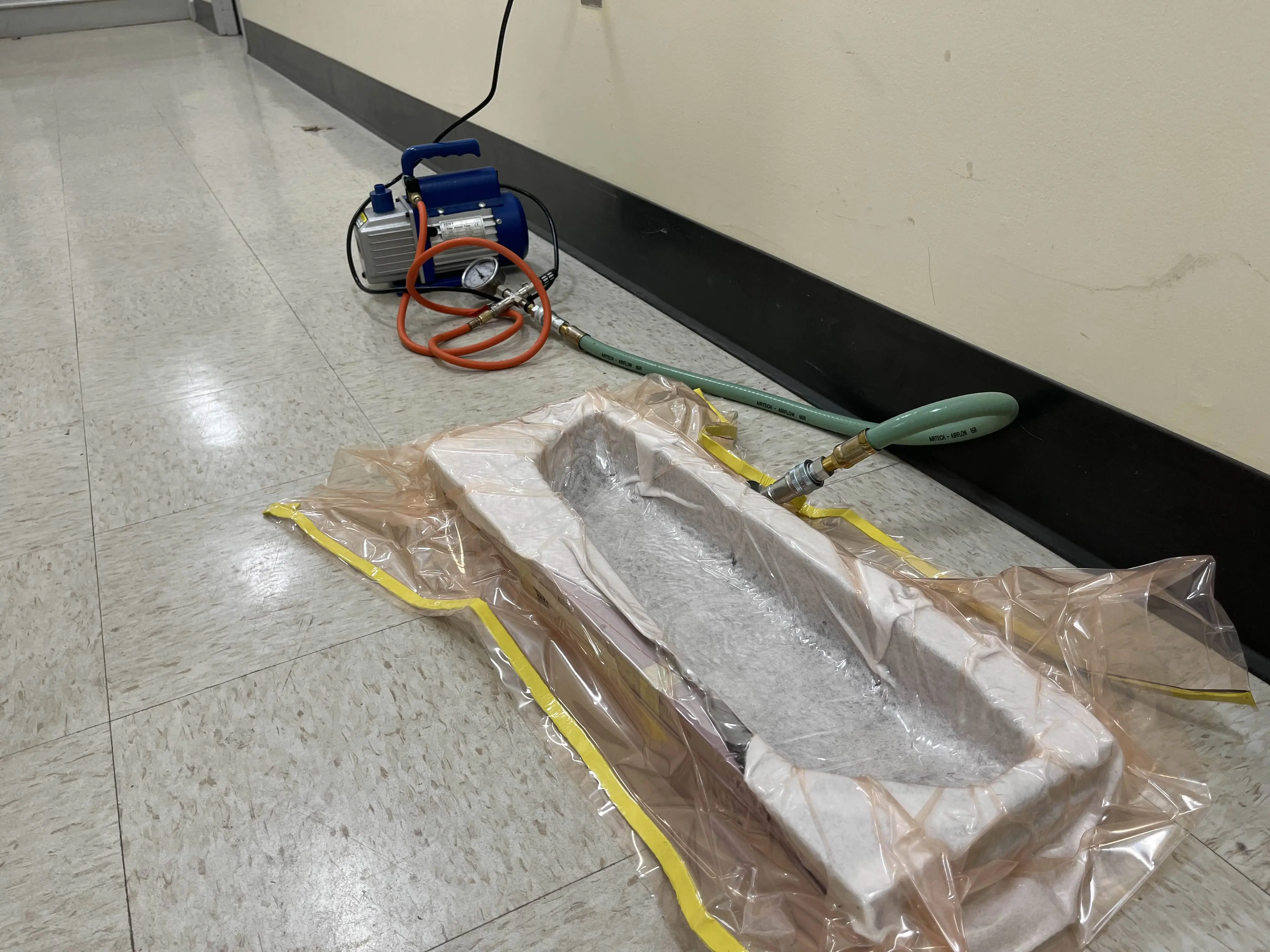

A scaled-down fuselage half was built to validate the manufacturing process and test structural integrity. We set up VCarve to CNC mill two female mold halves out of XPS foam. We then treated them with an epoxy coating to smooth out the surface and applied multiple layers of PVA as mold release agents. We performed a three-layer layup of bidirectional carbon fiber cloth in a 0/90°, ±45°, 0/90° orientation.

Scaled-down prototype

CNC milling the female mold halves

Wet layup process

Vacuum bagging technique

Structural Analysis

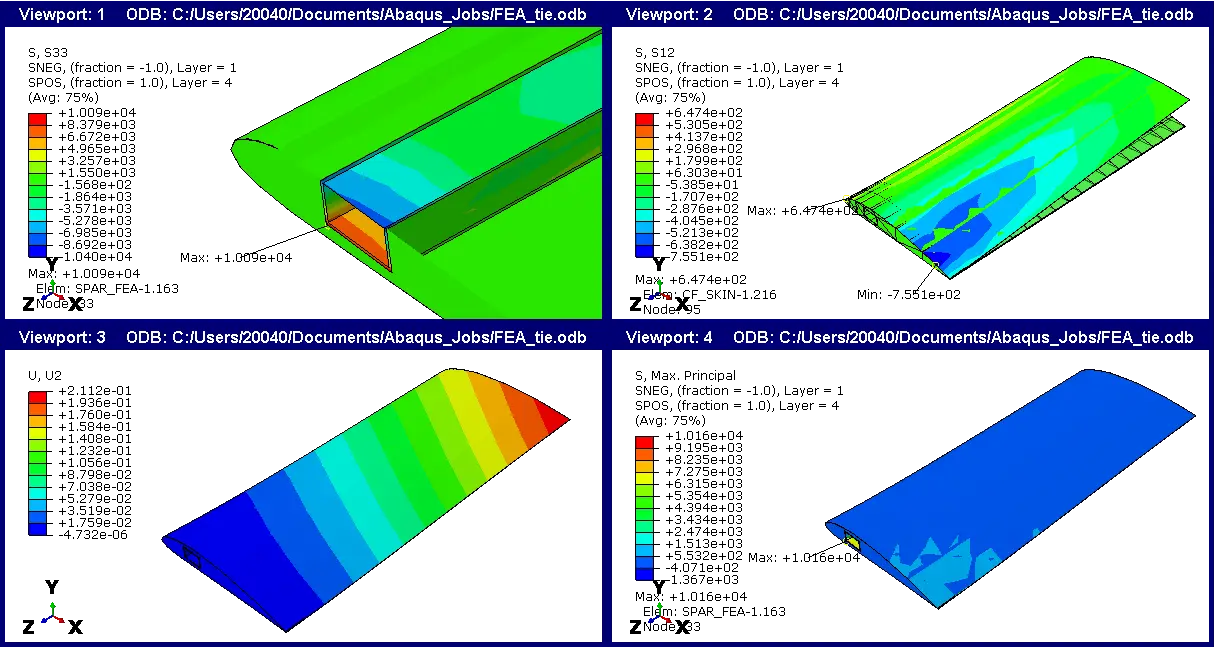

To validate the wing's structural design, we performed a Finite Element Analysis (FEA) in Abaqus. The model simulated an assembly of an XPS foam core insert, an internal carbon fiber spar, and a skin made from wet layup of two layers of ±45° bidirectional carbon fiber. A distributed lift force (scaled to simulate a 6G maneuver) calculated from aerodynamic parameters, was applied to the cantilevered wing structure. The results confirmed the design's integrity, showing minimal deflection and stress levels safely below material failure points.

Finite Element Analysis showing stress distribution under 6G load

Custom Manufacturing Tools

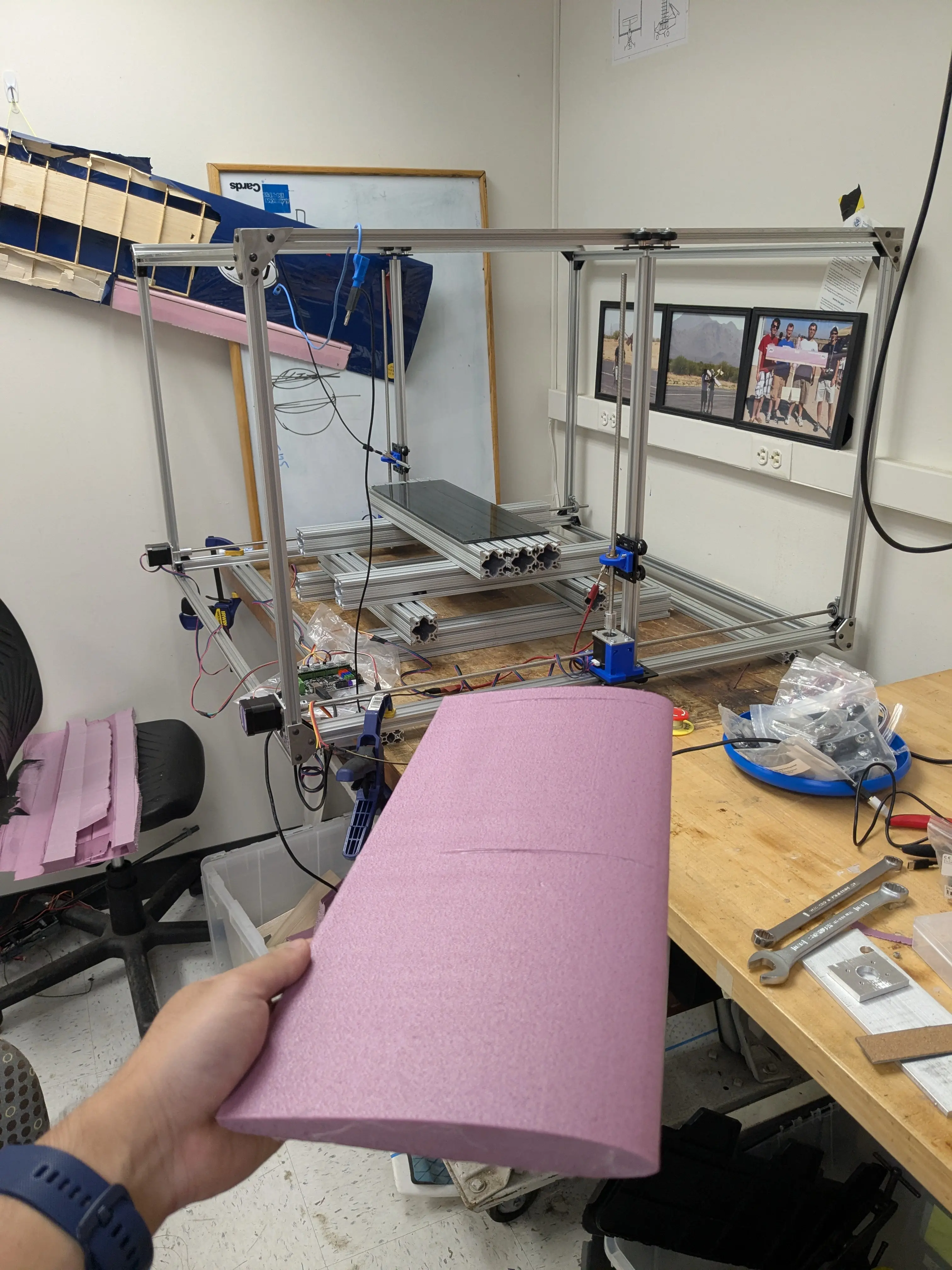

The wing is made out of carbon fiber wrapped XPS foam which is hot wire cut using our own custom CNC hot wire cutter. We even developed our own custom g-code generator as there is no open source software which satisfies our need that currently exists.

Using our custom-built CNC hot wire cutter controlled by in-house developed g-code generation software, we built our wing into highly specific airfoil shapes from XPS foam. We then wrapped the shaped foam with carbon fiber to achieve our rigorous structural requirements. Our specialized tools give us an advantage in manufacturing capacity and quality, as no existing tooling has been available for our needs until now.

Our custom-built CNC hot wire cutter

In-house developed g-code generator

Final carbon fiber fuselage prototype

Our 2026 Goal

Finish in the Top 20 Teams

With our fully carbon composite aircraft and innovative manufacturing techniques, we're positioned to compete with the best teams in the nation. Every day brings us closer to achieving this ambitious goal.